Carl Zeiss Jena 50mm f/2.8 strip down and clean

I received another camera and lens combination a couple of days ago – a Praktica LB fitted with a Carl Zeiss Jena 50mm f/2.8 zebra lens. When I received it the focus ring was completely locked and the aperture wouldn’t close, so this seemed to be another ideal candidate for a ‘strip down and clean’ post. It turned out this was a considerably more complex problem than the last lens I took apart and cleaned, although I’m pretty sure that it’s nowhere near as complex as trying to clean a zoom or a modern autofocus lens!

The unit I have is shown below – I think the camera is quite old since it has a light meter sensor attached to the front of the camera rather than having a through the lens arrangement, and the lens itself has a depth of field preview lever rather than a manual/auto switch. I found one other guide for cleaning a Carl Zeiss Jena, but it is a different version than the one I have.

Carl Zeiss Jena 50mm f/2.8 Images

Strip down

The first part of the strip down is to remove the front element which unscrews from the rest of the lens. My example actually came out quite easily, but it’s possible for this part to be quite difficult. If it is, just rest assured that it does unscrew so try something to add a bit of grip (not sandpaper!).

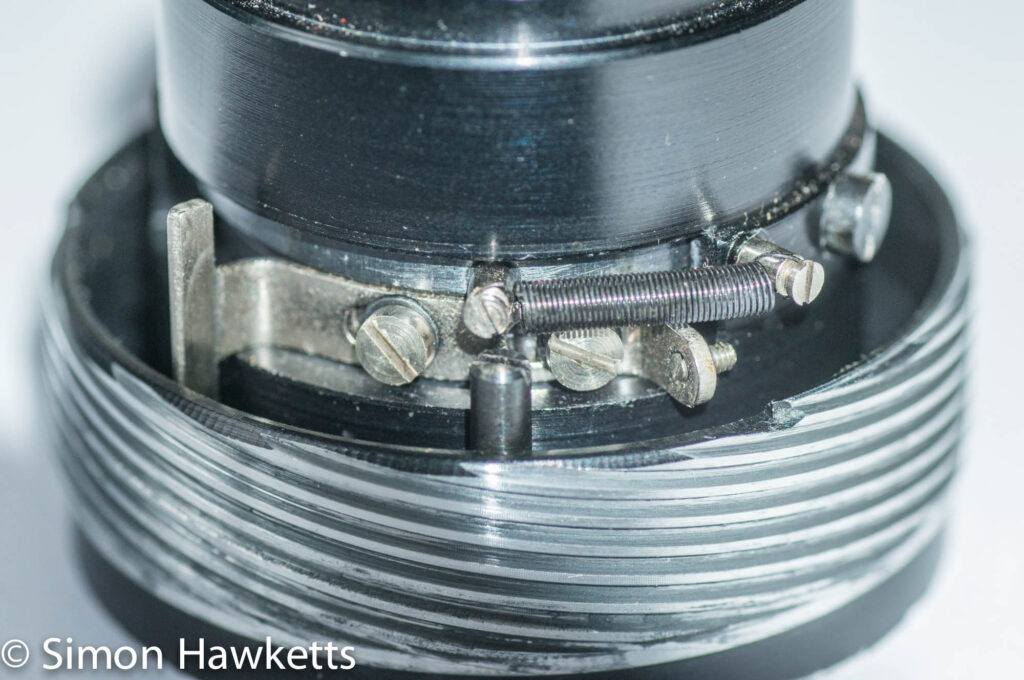

Once the front element is out, I turned the unit over and removed the three screws on the bottom of the lens and removed the bottom cover.

Once the bottom cover was off it revealed the mechanism for setting the aperture, and the bottom lens element which is mounted in the focus helicoid. The next part I tried to remove was this bottom lens element but I found that the focus ring stop prevented me from winding it all the way out of the lens. After a little investigation it turned out there was a locking ring mounted round the rear lens element and I needed to use a lens spanner to undo this. It had been sealed with a small dot of varnish so I needed to scrape that off first.

Once the locking ring was off I could remove the focusing ring and unscrew the front lens assembly helicoid.

To fix the sticky aperture blades I needed to carry on the disassembly of this bottom, so I could remove the actual iris blades. So to do this I put the unit flat on the desk (as shown below) and removed all the screws shown in this picture and the rear element lens shown at the top.

First I removed the small spring and the two screws which it attaches to. This is the spring which return the iris blades to the fully open position. With that off I could remove the aperture stop screw, a long screw into the bottom of the case, and the curved metal bracket which is fitted to the inner aperture adjustment disc with two screws with washers. As I took this off the rest of the aperture fell out of the lens assembly onto the white paper, so I realised I’d gone far enough!

At this point I had most of the bits of the lens apart so I also prised the aperture control ring off the lens (which has a couple of ball bearings and springs for the click stops so be careful), unscrewed the focus ring which the helicoid screws into and looked at what I had. Since there were several non optical, mechanical parts which needed cleaning I put them all into an ultrasonic cleaning bath with some hot water and a drop of washing up liquid and gave them a couple of 3 minute cleaning cycles. (Note: this didn’t include any of the iris components although some searching on the web suggests an ultrasonic bath is the ideal clean for iris blades).

Re-assembly

Reassembling the aperture blades

This was the trickiest part of the whole operation, but I believe that the following procedure should get you through it.

It’s important that the iris blades are not bent or deformed in any way, or they simply won’t work any more. Also, only pick the blades up with tweezers – don’t touch them with your fingers because the oil from your hands can actually etch the metal!

I spread a clean piece of white paper out and laid out the individual blades, so I could pick each one up in turn with tweezers and place in the correct location. The picture below shows the main parts of this assembly which are tweezers, lens bottom element assembly, iris blades, top aperture assembly.

You can see the bottom and top assemblies have a single larger hole which shows how the two parts align on re-assembly. This is not a precise alignment because the two parts move in relation to one another, but it shows in ballpark terms where the top part sits in relation to the bottom part.

I found for re-assembly the trick is to add each blade in turn into the lens housing making sure that each blade as you add it is fitted over the top of the one below. They have to be fitted so that the small spigot in the middle is fitted into the lens housing and the small spigot at the end of the blade is pointing upwards. (So I picked each blade up by the end spigot and fitted the spigot in the middle of the blade into the curved hole in the lens housing).

Once all the blades are in, arrange the blades so that the aperture is set to maximum (i.e. f/2.8). Once they are in place, the other part of the assembly can be dropped into place over the top and slightly moving each blade so the small holes in the top assembly fit the small spigots.

This is not easy to do; I did it all once and then turned the unit over and the whole assembly fell apart again! Once I had it all in place a second time I fitted the other parts which normally fit over the top of the assembly and re-screwed the front lens assembly back into place, so the aperture didn’t move out of place as I moved it around.

Once this was in place I could re-assemble all the mechanics of the aperture and I had a fully assembled aperture again. This picture below shows the blades re-assembled and also shows a small cardboard circle I made and pushed into the hole I was assembling the blades over thinking it would give some support to the blades. I wondered if this would help but to be honest I’m not sure if it did.

I seemed to be fortunate because once the iris was re-assembled it seems to work quite nicely. There doesn’t seem to be any stickiness or delay in operation. I guess if the blades have any oily deposits they would need to be cleaned prior to re-assembly.

Helicoid re-assembly.

Once the aperture was re-assembled I had to fit the helicoid assembly back into the lens body. The first thing I did was apply a very small amount of lithium based grease to the helicoid and to the focus adjustment ring so that they moved more easily in the lens body. Once the grease was on I fitted the helicoid into the focus ring and worked it up and down a few times to get the grease distributed and then removed it and did the same with the focus ring and the lens body. Then I screwed the focus ring into the body, so it was almost fully screwed in and fitted the aperture / front element assembly helicoid into the focus ring.

In order for the assembly to fit properly you need to look at it from below and fit the black screw head in the front lens assembly into the brass runner shown (slightly out of focus unfortunately) at the back in the photo below.

This brass runner is the part which forces the rotation of the focus ring to turn the helicoid and push the lens front assembly in and out. Fitting the front lens into this part is tricky until you’ve done it a few times. You need to get the front assembly so the black screw lines up with the brass runner and then turn it, and at the same time the focus ring, until the two engage and turning the focus ring by itself pulls the front element back into the lens. You also need to make sure the lever which operates the aperture (shown in the right hand picture above on the right-hand side) is fully pulled up, so it properly engages with the aperture lever on the front lens assembly.

As I say it’s easier once you’ve done it a few times, and you almost certainly will do it a few times because once the front assembly is in-place you need to test it for infinity focus and if it’s not right you need to unscrew it, turn it 1/6 of a turn and try the next helicoid thread until it does focus to infinity.

On my particular example I had to do it twice to get it right – but each time in order to adjust the focus I needed to re assemble the focus adjustment ring, fit the locking ring and re-assemble the lens mount to test it, so I was glad it was only twice!

Mount re-assembly.

The re-assembly of the mount is actually quite straight forward, you just do the opposite of taking it apart. However, I discovered that the small spring which the aperture adjustment ball bearing sits in is damaged, so I couldn’t actually get the aperture click stop adjustment to work. I will need to acquire a small spring from somewhere and re-fit the aperture ring.

Once re-assembled I found the focus to be much easier to adjust – well I could adjust it which I couldn’t before, so it’s a huge improvement! However, in the course of cleaning the rest of the lens and adding grease etc. I’ve neglected the lens glass elements, and they have several dirty marks and smudges on them, so I’m going to remove them and give them a thorough clean before I try shooting with this lens. When I do that I will attach the pictures to this post.

Discover more from Everything Vintage

Subscribe to get the latest posts sent to your email.